Everybody seems to be comparing the transformative potential of artificial intelligence to electricity—a foundational technology that reshaped industries and societies.

But as much as AI promises to revolutionize the way we work and live, its adoption is likely to be slow, just like the historical shift from steam-powered to electric factories.

For organizations willing to make the leap early, this slow pace of change can offer a sustained competitive edge.

Learning the Lessons of History

Thomas Edison and Joseph Swan independently invented usable light bulbs in the late 1870s, and by 1881, Edison had built electricity-generating stations in Manhattan and London. Within a year, electricity was being sold as a commodity, and by 1882, electric motors began driving manufacturing machinery.

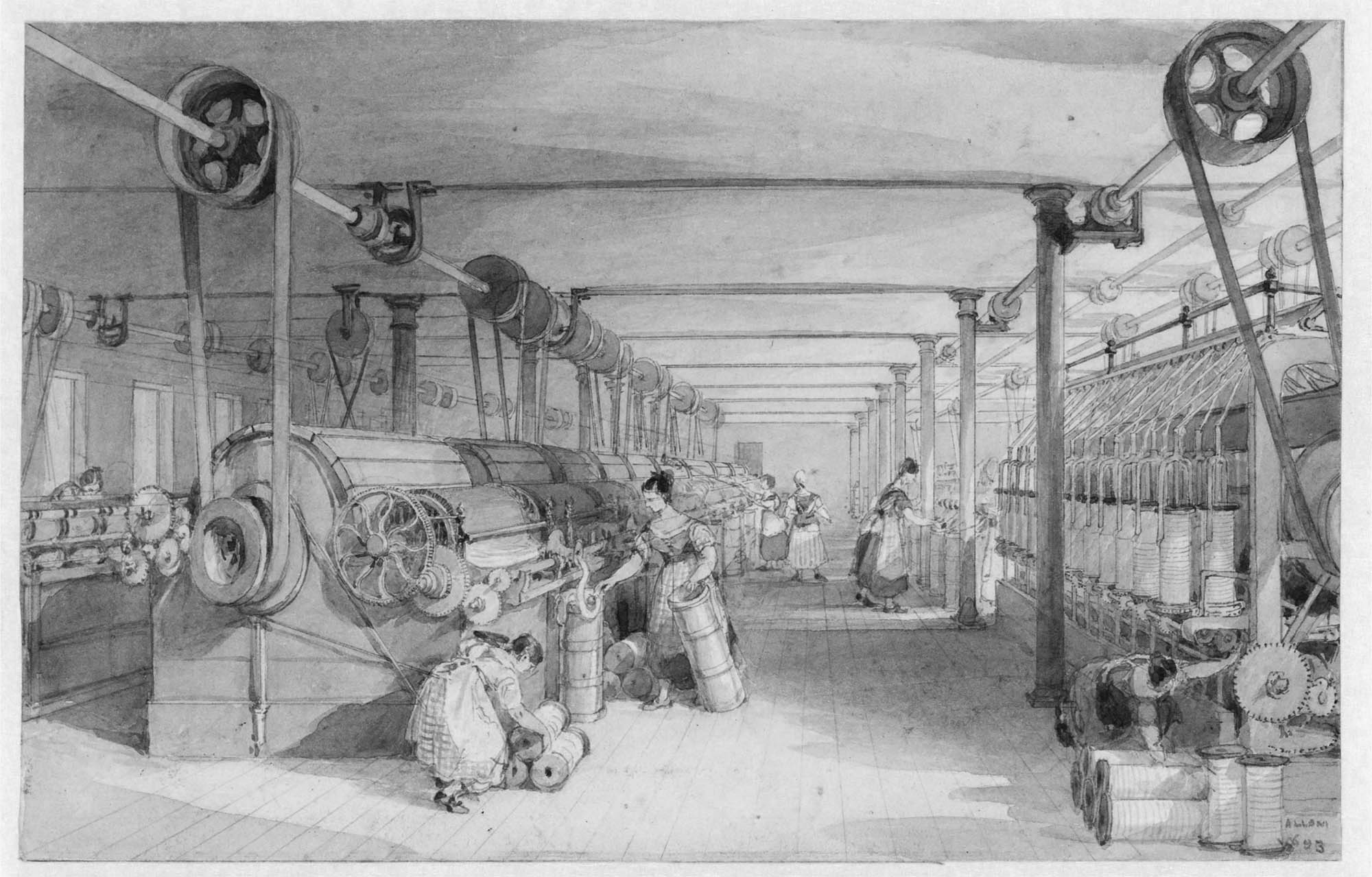

So did this drive massive changes in industry? No. At least not right away. Despite this groundbreaking innovation, less than 5% of mechanical drive power in American factories came from electric motors by 1900. Steam power persisted, with massive engines turning central drive shafts that powered entire factories through a complex system of belts and gears. These setups were awe-inspiring in their scale but inefficient and dangerous.

While some factory owners adopted electric motors early, they often found the savings disappointing. Using electricity as a simple replacement for steam engines failed to deliver the expected benefits.

Tim Harford explains:

“In order to take advantage of electricity, factory owners had to think in a very different way. They could, of course, use an electric motor in the same way as they used steam engines. It would slot right into their old systems.

But electric motors could do much more. Electricity allowed power to be delivered exactly where and when it was needed.

Small steam engines were hopelessly inefficient but small electric motors worked just fine. So a factory could contain several smaller motors, each driving a small drive shaft.

Electricity meant you could organise factories – and workers – along the logic of a production line

As the technology developed, every workbench could have its own machine tool with its own little electric motor.

Power wasn’t transmitted through a single, massive spinning drive shaft but through wires.

A factory powered by steam needed to be sturdy enough to carry huge steel drive shafts. One powered by electricity could be light and airy.

Steam-powered factories had to be arranged on the logic of the driveshaft. Electricity meant you could organise factories on the logic of a production line.

Old factories were dark and dense, packed around the shafts. New factories could spread out, with wings and windows allowing natural light and air. In the old factories, the steam engine set the pace. In the new factories, workers could do so.”

To truly harness the potential of electricity, manufacturers had to rethink everything—from production processes to factory architecture and even labor practices. This required massive investments and a willingness to abandon long-standing systems and mindsets.

As a result, widespread adoption did not occur until the 1920s, nearly half a century after electricity’s initial introduction.

Parallels with AI Adoption

AI is following a similar trajectory. Like electricity, it is a general-purpose technology with applications across industries. However, reaping its full benefits requires more than simply “plugging it in” to existing workflows. Organizations must overhaul processes, retrain employees, and adopt new ways of thinking about operations and strategy.

For example, AI-powered tools can automate data analysis, customer service, and supply chain management. But integrating these tools effectively requires significant changes to organizational structures and a shift in decision-making processes. J

ust as steam-powered factories couldn’t fully exploit electric motors without reconfiguring their layouts, companies today won’t unlock AI’s potential without reimagining their operations.

Barriers to Change

Several factors slow AI adoption, much as they did with electricity:

- Existing Investments: Organizations are hesitant to abandon their current systems, which represent significant capital investments. Just as steam-powered factories were reluctant to scrap massive drive shafts, companies today are cautious about replacing legacy systems with AI solutions.

- Skill Gaps: Leveraging AI requires a workforce skilled in data science, machine learning, and related disciplines. Similarly, early 20th-century factories needed workers trained to operate and maintain electric motors.

- Cultural Resistance: Adopting AI often requires a shift in corporate culture, encouraging experimentation and data-driven decision-making. This is no small task in organizations accustomed to traditional workflows.

- Uncertain ROI: Many companies struggle to quantify the immediate benefits of AI, making it difficult to justify the initial investment. Early adopters of electricity faced similar challenges when the cost savings didn’t materialize immediately.

The Competitive Advantage of Early Adopters

Despite these barriers, history shows that early adopters can gain lasting advantages. Companies that embraced electricity and reimagined their factories saw unprecedented productivity gains by the 1920s. Similarly, organizations willing to make the necessary investments in AI today will be well-positioned to outpace their competitors in the coming decades.

For example, early AI adopters are already seeing benefits such as enhanced customer experiences, improved operational efficiency, and more accurate forecasting. These organizations are not just implementing AI but are also transforming their business models to align with its capabilities.

Navigating the Transition

To successfully adopt AI, organizations can take the following steps:

- Start Small: Begin with pilot projects that demonstrate clear, measurable value. This builds confidence and creates momentum for larger-scale initiatives.

- Invest in Training: Equip employees with the skills needed to work alongside AI. This includes technical training as well as fostering an understanding of AI’s strategic implications.

- Reimagine Processes: Don’t simply layer AI onto existing workflows. Identify areas where AI can enable entirely new ways of working.

- Be Patient: Recognize that the benefits of AI may take time to materialize, just as it took decades for electricity to transform manufacturing.

Conclusion

AI, like electricity, has the potential to reshape industries and societies. But realizing this potential requires time, effort, and a willingness to rethink entrenched systems. Organizations that embrace AI early and commit to meaningful transformation will not only navigate the slow adoption process but also secure a lasting competitive advantage.

For those bold enough to lead the charge, the rewards could be as transformative as the leap from steam to electricity over a century ago.

Image credit: CC BY-NC-SA 4.0 Science Museum Group, black and white version